Case Study

Rotating furnace

Rotating furnace

Challenge

Rotating furnaces are widely used in the metallurgy industry, and the ability to operate the furnace is critical to fully control the process. This Case study describes how Uninterruptible Motor Drive (UMD™) secures power supply to a rotating furnace within the metallurgy industry.

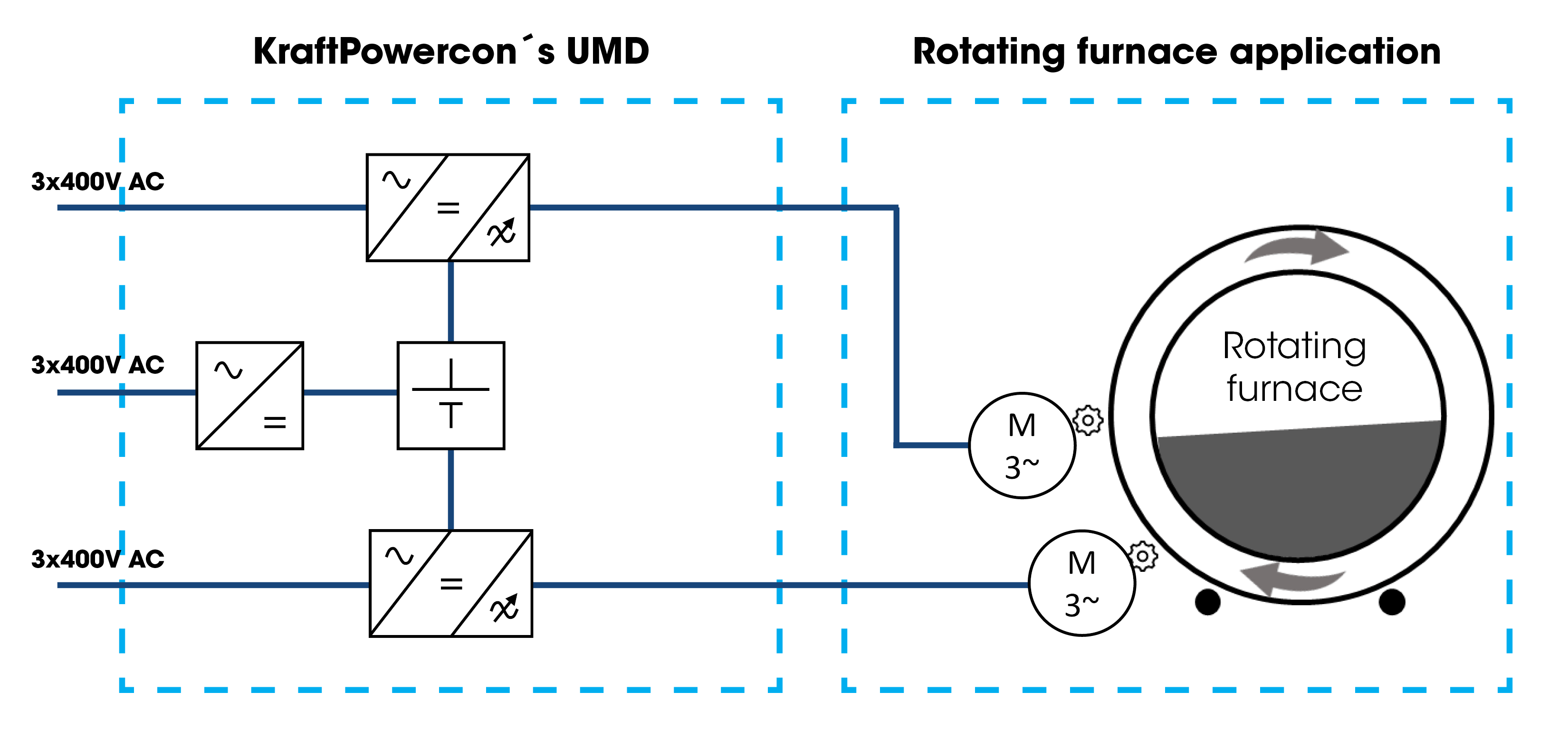

Uninterruptible Motor Drive – SLD Solution

Uninterruptible Motor Drive

The UMD™ system will be used to operate the motor drive system for the furnace, which includes two larger AC motors. In the case of a power outage, the battery will automatically and seamlessly take over the supply for the motors, the 230VAC inverter, and the 24VDC auxiliary power. The system will also indicate to the control system cabinet that it is running in DC-backup mode.

In the event that one of the motor fails, the system is designed to switch to independent operation. This allows the remaining motor to handle emergency operations on its own. To manage the energy in the furnace, the system is equipped with a braking chopper and brake resistor, which are housed in a dedicated enclosure.

Benefits

- Standardized, Type Tested Systems

- Highest Possible Availability

- Eliminates Single Point of Failure

The UMD™ is supplied as a single, factory-tested unit that has been tested according to various standards, including IEC, UL, and CSA. The system also includes single or redundant main input breakers, a battery charger, AC and DC busbars, and the necessary motor drive outputs.

“Faced with a challenging technical task, we cooperate with the customer to deliver a UMD solution that perfectly meets the needs and improves the rotating furnace operation.”

Håkan Rydenborg - Technical Sales Manager, KraftPowercon