Coal-fired Power Plant

While coal-fired plants are the most common ESP applications, they present varying types of challenges. Coal from one area can be very different from that of another mine. As a result, the ash and gas characteristics, including electrical properties, show huge variations. Put short, the quality of the coal affects resistivity, particle size, and voltage withstand strength. One example is that some coal ash grades usually degenerates into back corona, while others rarely do. Therefore, it’s imperative to choose the right type of power supply based on the type of coal used in the plant. A choice also affects dealing with the main challenge of high emission levels and secondary challenges such as maintenance costs and ID fans’ life span.

Emissions

By upgrading your ESP with our power supplies, you can minimize the emission levels, making it easier to meet more demanding environmental norms.

Economy

Our power supplies reduce energy consumption while increasing your operations' efficiency and output without adding ESP fields. Something that makes them a sound financial investment.

Reliability

By upgrading to our power supplies, you get a highly reliable solution adapted to your unique needs. The result? Better uptime and more predictable and profitable operations.

How our solutions tackle various challenges

Different types of coal

Some grades of coal result in low Sulphur, low moisture, and high ash content. This often leads to back corona. The ESPs for those are traditionally designed with very high specific collection areas. The electrical solution is to provide right level of corona power to prevent back corona. With lignite and other grades of coal, the result is high Sulphur and high moisture. Here the key is to operate at medium or low resistive range with high voltage withstand capacity.

Back corona

Some grades of coal usually have the drawback of back corona. To solve that issue, KraftPowercon offers power supplies with pulse technology combined with profound application knowledge.

Maintenance costs

Quite a few ESP installations are old and use power supplies in need of costly maintenance. Traditionally, you replace the entire installation with a new one, but we offer a quicker, more cost-effective solution where we only upgrade the power supply. You pay less than you would for retrofit or rebuilding the ESP – and get a more reliable solution that improves your operations and minimizes your energy consumption.

ID fans

Power supplies are periodically turned off, run at reduced power, or go down. All these lead to high spiking of Particulate Matter (PM), which erodes the ID fan blades and increases scrubber wear. You can solve this with an increased blowdown, but that incurs higher installation costs. With a state-of-the-art power supply from us, you get 100% availability. A solution that prolongs the life span of ID fans, reduces scrubber blowdown and maintenance costs and ensures that the ESP continuously maintains the lowest particulate emissions.

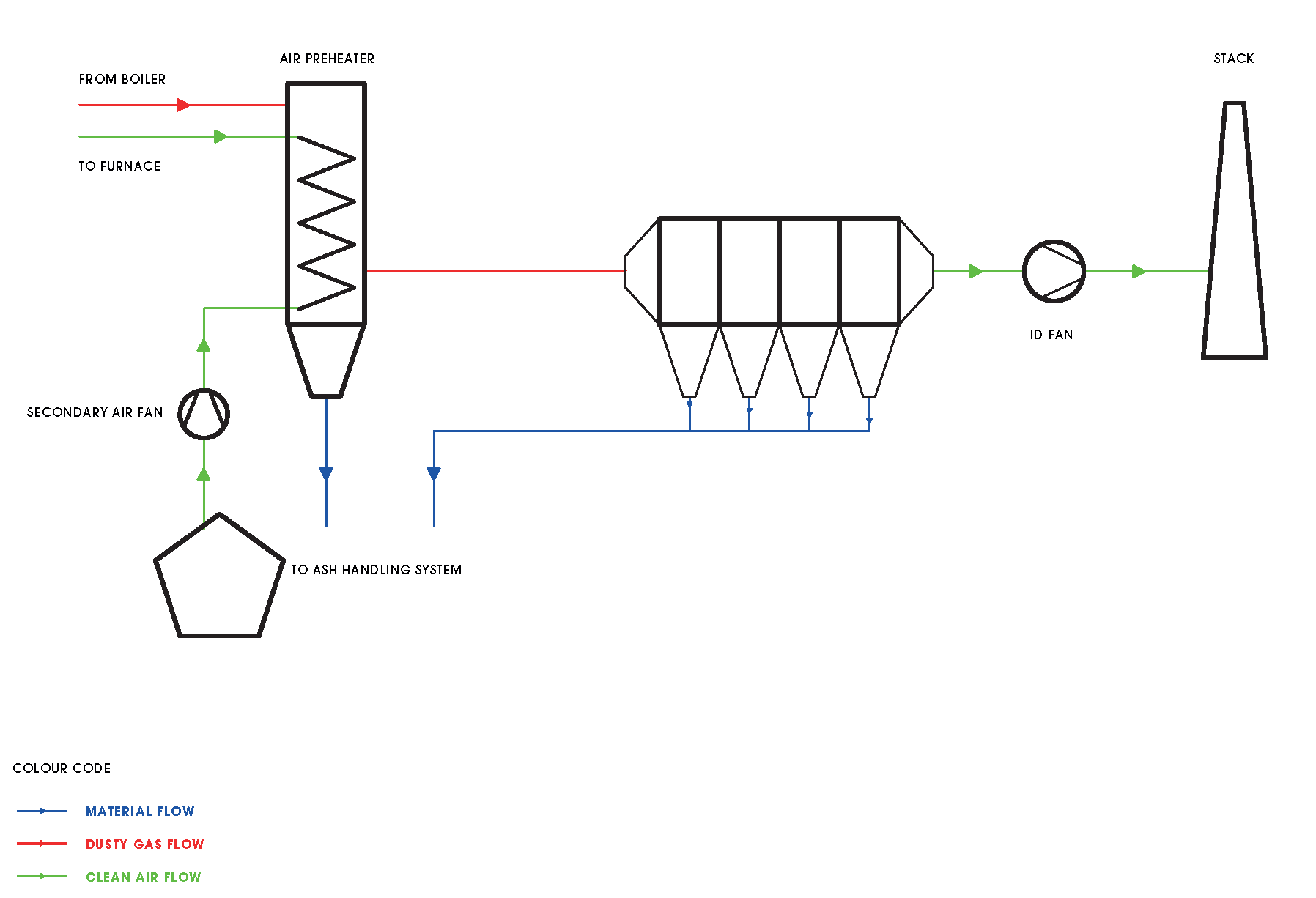

TYPICAL PROCESS FLOW DIAGRAM OF BOILER ESP SYSTEM

Electrostatic precipitators (ESPs)

- Quick assistance

Our latest posts on LinkedIn